Comparing Fiber and UV Laser Marking Technologies

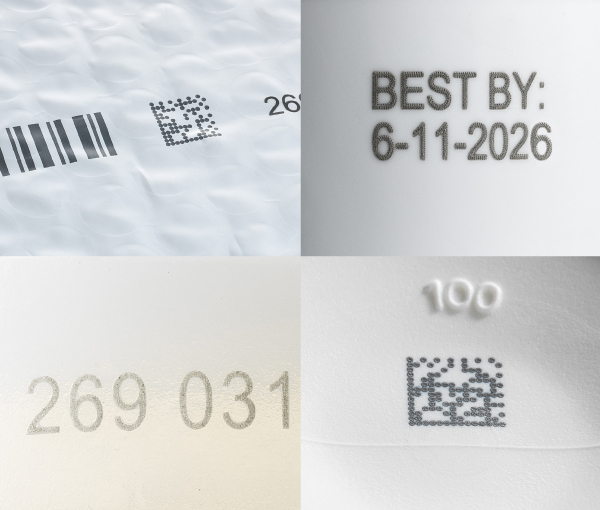

Laser marking has emerged as a non-contact printing technique that is capable of engraving high-quality 1D barcodes, 2D codes including QR and GS1 DataMatrix, multiple lines of text, batch numbers, lot codes, logos, and more on a variety of products. This process not only provides essential product information and identification with permanent codes, but it can also help ensure traceability. Lasers vary in power outputs to cater to different substrates and applications. Among the most widely used in the industry are fiber and UV lasers—both of which rely on solid-state technology.

Solid-state lasers differ from CO2 and other gas lasers primarily because they use a solid as their active lasing medium, such as a crystal or an optical fiber, instead of a gas or a mixture of gases. Solid-state lasers, including fiber and UV lasers, are known for their efficiency and quality in marking various materials that are a challenge for CO2 lasers, like metal and flexible film.

Today’s fiber lasers designed for marking products boast an average source life up to 100,000 hours. They are particularly adept at marking codes and other information on robust, high-density materials like metal and hard or dark-coloured plastics. This makes them suitable for marking parts, consumer packaged goods (CPG), extruded pipes, and pharmaceuticals. Fiber lasers can keep pace with demanding production schedules and deliver a high level of code contrast.

The Videojet fiber laser range includes models that can mark at speeds up to 2,000 characters per second, depending on the marking head size and substrate. They offer excellent beam distribution and can maintain high-quality codes within their usable depth of field. Laser beams with an enhanced depth of field offer manufacturers the benefit of coding products with minimal worry about re-focusing the laser or inconsistent product placement.

Metal

When marking on metal cans and parts, fiber lasers are often used to engrave or anneal. Annealing creates contrast by applying localised heat that leads to oxidation. Fiber lasers can also remove material to produce a mark’s contrast. On certain materials like stainless steel, different colours can be achieved by manipulating the laser parameters, such as pulse frequency. This versatility is especially beneficial in the automotive and aerospace industries for tracking parts. While UV lasers cannot achieve the colour changes of fiber lasers, they can perform simple engraving on many metal surfaces.

Plastic

With certain plastics, fiber lasers cause the material to “foam” and create contrast through the formation of air or gas bubbles. On other plastic surfaces, a colour change can be achieved.

When it comes to marking on plastic bottles and plastic parts, UV lasers offer a different mechanism. They can induce a photochemical reaction with a minimal emission of smoke and fumes, and are ideal for marking on high-density polyethylene (HDPE), low-density polyethylene (LDPE) and synthetic fiber materials. New and innovative lasers, like the Videojet 7920 UV laser, are also adept at marking on flexible films and materials with an enhanced potential for recyclability, such as mono-materials.

Stay ahead with real-time updates on the latest news:

Glass

Crucial for product integrity and ideal for fighting counterfeit products, UV lasers excel at marking on glass without causing flaking or micro-cracking. Fiber lasers are generally not suitable for marking on glass in packaging or manufacturing operations because the glass will not absorb a fiber laser’s wavelength.

Integration

When comparing fiber to UV lasers, it’s important to consider the specific requirements of the application and the manufacturing environment in which they are installed. Both laser technologies are offered in models with various marking head sizes and orientations to accommodate a multitude of applications and space limitations. Fiber lasers feature some of the widest marking fields available, allowing more text and larger barcodes and graphics to be marked in a single pass. Innovations such as Videojet SmartFocus™ technology, available with the Videojet 7920 UV laser, allow different-sized products to be marked in the same marking field and auto-adjusts the laser’s focal distance after a job is set up.

Marks produced by both fiber and UV lasers consistently meet the quality requirements for optimal vision system readability. While fiber lasers are well-suited for high-density materials and applications requiring high-speed marking and deep contrast, UV lasers are ideal for sensitive materials where minimal heat application is desired. The choice between fiber and UV lasers should be based on the specific requirements of the production environment, the materials to be marked, and testing with samples. To help with laser selection, Videojet operates state-of-the-art sample labs in five locations around the world to replicate Videojet customers’ applications and test code quality under variable real-world conditions.