Videojet’s range of Thermal Transfer Overprinter (TTO) ribbons are designed specifically to meet the challenges of flexible packaging applications. Featuring backcoat technology, Videojet ribbons are optimised for use with Videojet printers, and when used together, the combination helps ensure fewer ribbon breaks, better print quality, optimised adhesion and the uptime performance your operation demands.

- Ribbon Selector

- Backcoat Technology

- Documents

Ribbon Selection Table

| Videojet Ultra Ribbon | Videojet Standard Ribbon | Videojet Super Standard Ribbon | Videojet Premium Ribbon | Videojet Extreme Temp Ribbon | |

|---|---|---|---|---|---|

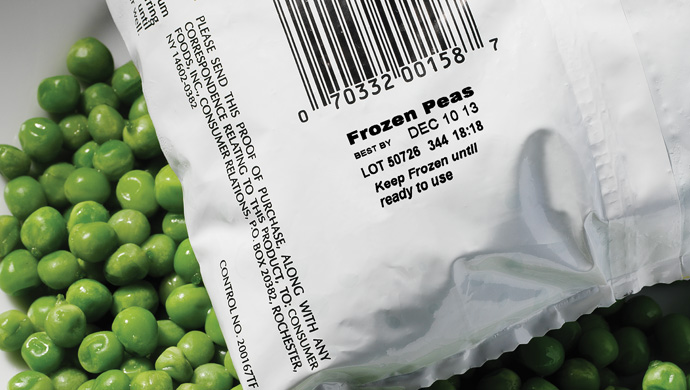

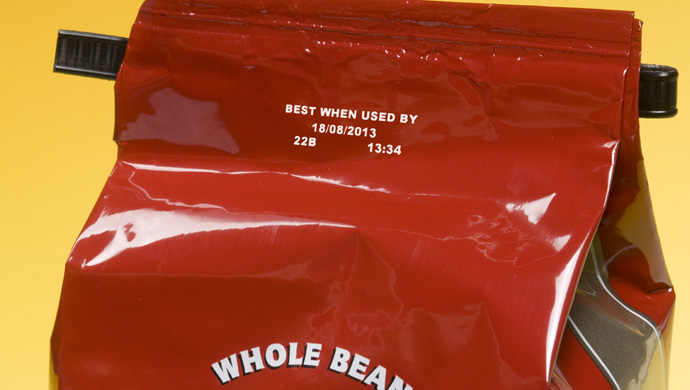

| Use | High performance ribbon for general purpose applications | General use solution for mid-range speeds | Extra adhesion and superior durability, recommended when printing on a variety of film types and speeds | Ideal for applications where adhesion is critical; well-suited for packages in harsh environments | Optimal choice for hot-fill applications 180 – 195°F |

| Applications | Salty/savoury bagged snacks, meat and poultry, wrapped confectionery products, snack bars, nuts | Salty/savoury bagged snacks, fresh and frozen foods, meat and poultry, dried fruit, candy | Materials with smooth/glossy labels, pharmaceutical and nutraceutical labels and packages, trail mix, cosmetic/ shampoo labels, nutrition and ingredients statements | Glossy/shiny packaging, pharmaceuticals, medical devices, automotive, high end cosmetics | Fresh-made soups and packages filled with hot products |

| Print Speed (mm/s) | 1000 | 800 | 800 | 400 | 200 |

| Substrate Compatibility | □ | □ | □ | ◊ | ○ |

| 90° Bar Code Definition | □ | ◊ | □ | □ | □ |

| Blackness/ Contrast | □ | □ | ◊ | ○ | ◊ |

| Smudge Resistance | □ | ◊ | □ | □ | ◊ |

| Scratch Resistance | ◊ | ○ | ◊ | □ | ◊ |

| Number of Available Colors | 1 | 10 | 2 | 5 | 1 |

| □ | Superior results | ◊ | Very good results | ○ | Good results |

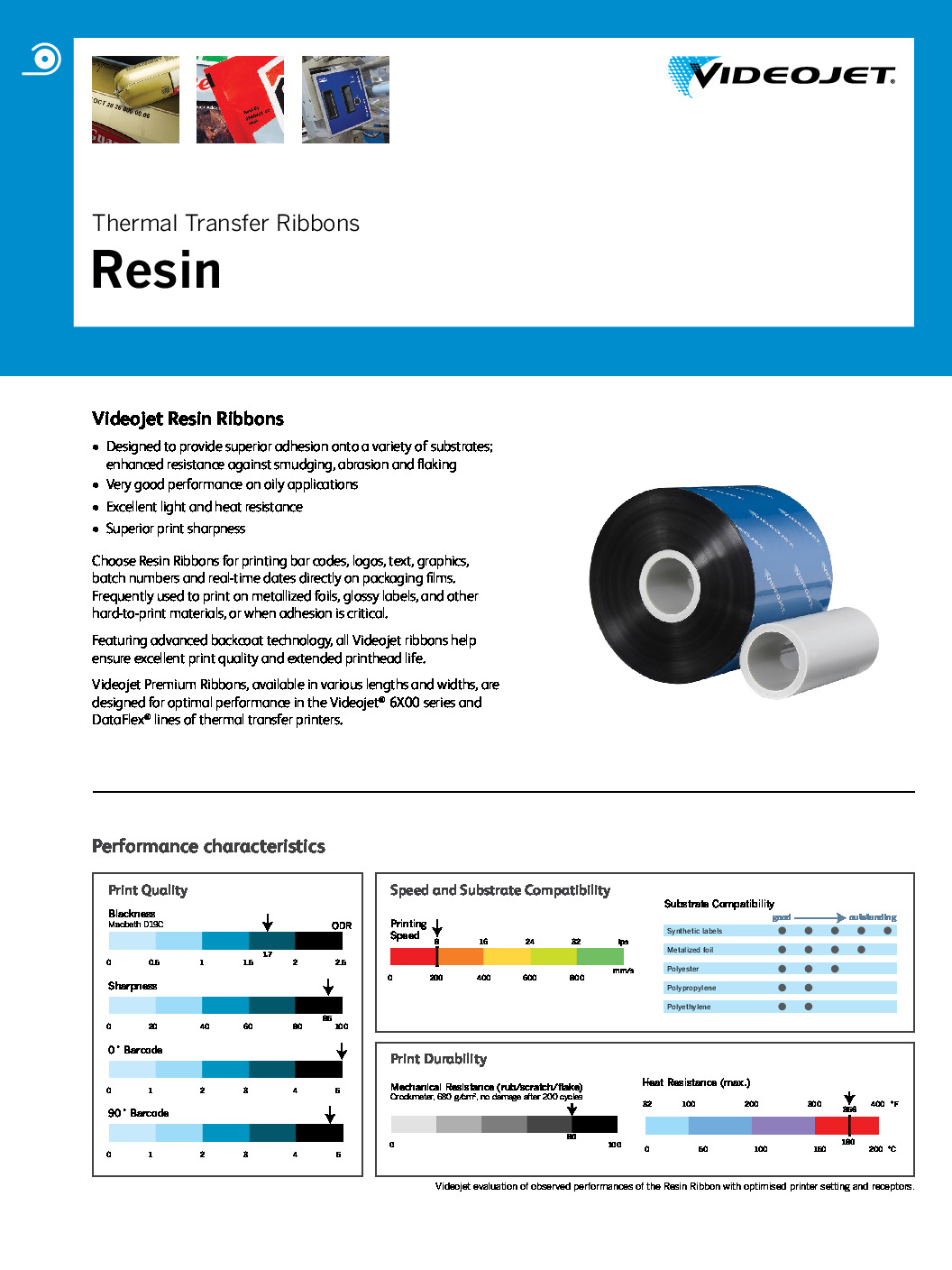

Advantages of Videojet ribbons with backcoat technology

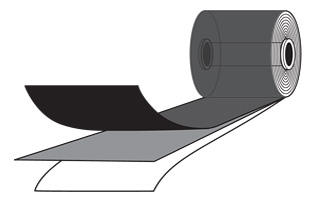

Not all Thermal Transfer Ribbons are made the same. Ribbon selection matters since it impacts the life of the TT printhead, the quality of the code, and ultimately the uptime of the packaging line. All Videojet ribbons feature advanced backcoat technology, a non-abrasive silicone-based coating that:

- provides for optimal thermal conduction for ink transfer and optimal code quality

- protects the printhead

- extends printhead life

- helps to dissipate static charge (which can damage the printhead and degrade code quality)

Backcoating

Carrier

Ink layer(s)

Contact Us

Equipment Sales:

01267 6687

Service & Support:

+353 1 267 6503 (Republic of Ireland)

03301233930 (Northern Ireland)