Thermal Inkjet Printer (TIJ)

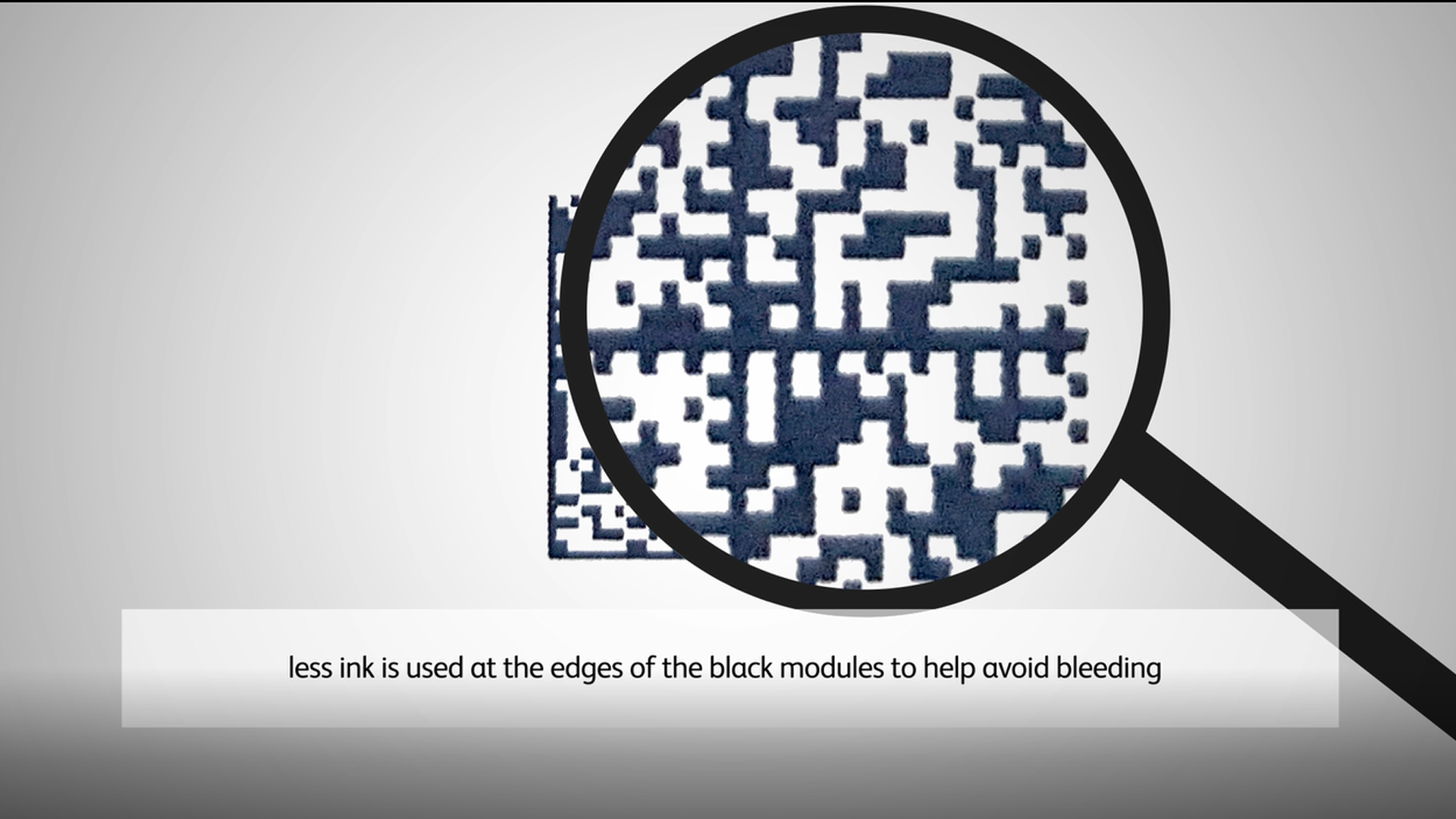

Thermal inkjet (TIJ) printing technology is an ideal fit for applications where high-quality print is essential and ease of use is a primary consideration. It has been selected by pharmaceutical companies for years due to its ability to deliver consistent, high-resolution codes (up to 600 dpi) at industry standard line speeds, its simple, clean cartridge changes for clean rooms, no wear parts for reliable production, and flexible configurations for integration into complex machinery.

Wolke by Videojet TIJ printers offer superior print quality with clean, no-mess operation and solid-state electronics requiring no controller maintenance. They allow for more complex coding options and the ability to print linear bar codes, alternate fonts, logos, and 2-dimensional codes such as GS1 DataMatrix and QR codes.

Contact Us

Equipment Sales:

01267 6687

Service & Support:

+353 1 267 6503 (Republic of Ireland)

03301233930 (Northern Ireland)

- Brochures

- Spec Sheets

- Application Notes

- Case Studies

- White Paper

- Line Integration

- Videos

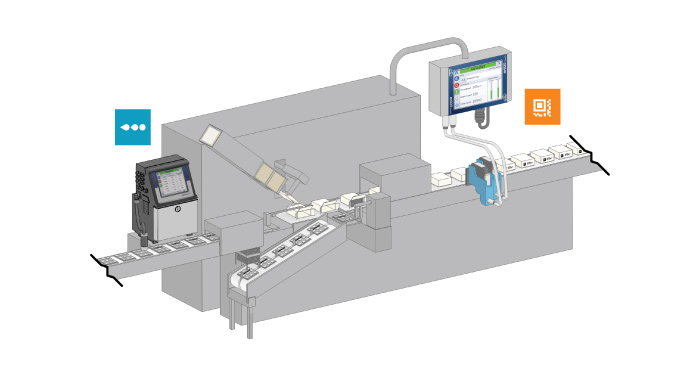

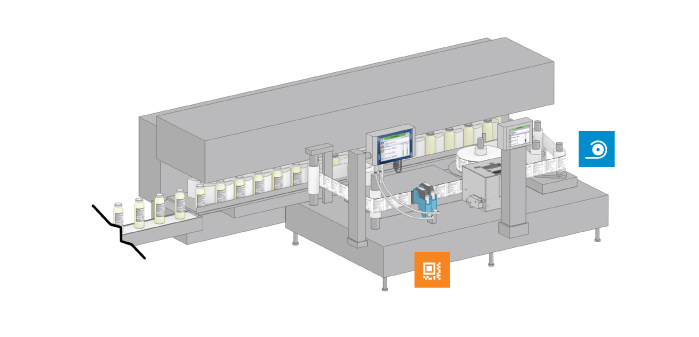

- Cartoner

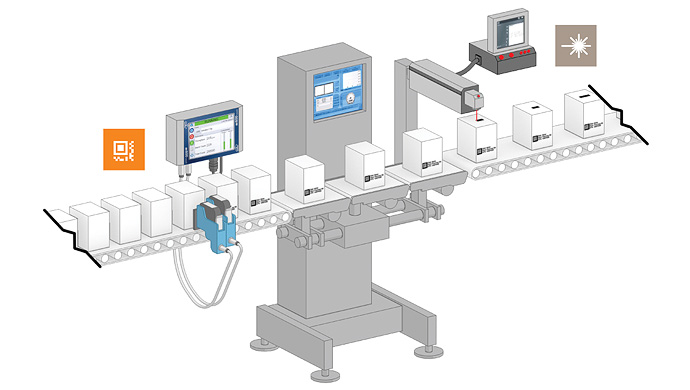

- Checkweigher

- Bottle Labeler

- Thermoformer

Coding may occur in several locations, either integrated into the cartoner itself or on the outfeed conveyor. Printing may also occur upstream of the cartoner on the primary pack as required.

Continuous inkjet (CIJ)

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

Thermal inkjet (TIJ)

Ink-based, non-contact printing using heat and surface tension to move ink onto a package surface. Generally used to print 2D DataMatrix and other bar codes.

Code integration with checkweighing equipment leverages the checkweigher’s precise material handling to improve overall print and DataMatrix quality.

Thermal inkjet (TIJ)

Ink-based, non-contact printing using heat and surface tension to move ink onto a package surface. Generally used to print 2D DataMatrix and other bar codes.

Laser Marking Systems

A beam of infrared light focused and steered with a series of carefully controlled small mirrors to create marks where the heat of the beam interacts with the packaging surface.

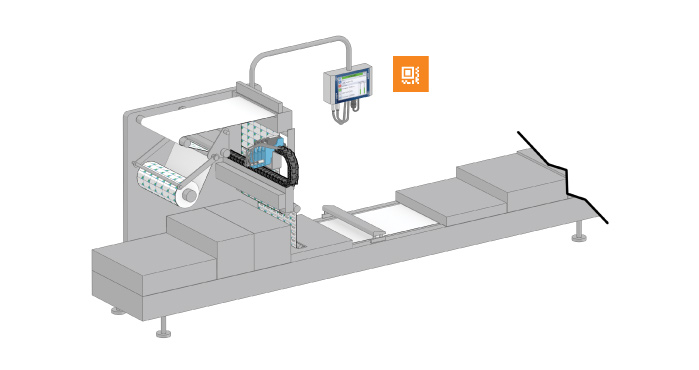

Several coding technologies can be utilized for contact or non-contact marking of the label before application. Precise label control facilitates high quality alphanumeric and bar code printing.

Thermal inkjet (TIJ)

Ink-based, non-contact printing using heat and surface tension to move ink onto a package surface. Generally used to print 2D DataMatrix and other bar codes.

Thermal Transfer Overprinting (TTO)

A digitally controlled printhead precisely melts ink from a ribbon directly onto flexible films to provide high resolution, real-time prints.

Precise mechanical and controls integration helps ensure high quality marking on web-based materials, including blister lidding foils and other barrier films.

Thermal inkjet (TIJ)

Ink-based, non-contact printing using heat and surface tension to move ink onto a package surface. Generally used to print 2D DataMatrix and other bar codes.