Egg Coding

Coding technologies for the egg industry have evolved over the years, but the focus on food safety has remained paramount. Advances in these technologies have provided improved print quality to better communicate important expiry and traceability data and to help ensure compliance with evolving government regulations regarding producer accountability. Videojet’s egg coders can help meet these coding needs while providing high quality printing to aid brand image and high uptime to ensure efficient operations.

- Applications

- Line Integrations

- Documents

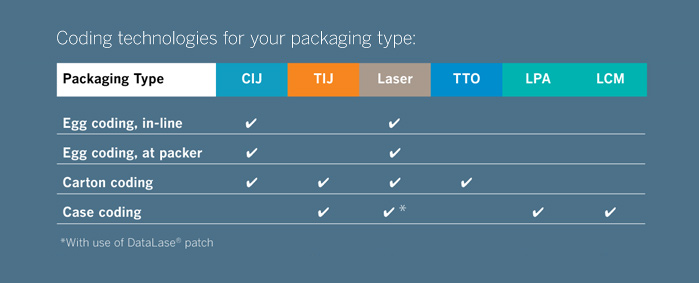

- Overview

- Egg

- Carton

- Case

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

Thermal Transfer Overprinting (TTO)

A digitally controlled printhead precisely melts ink from a ribbon directly onto flexible films to provide high resolution, real-time prints.

Ink-based, non-contact printing using heat and surface tension to move ink onto a package surface. Generally used to print 2D DataMatrix and other bar codes.

Ink-based, non-contact printing of multiple data types (alphanumeric, logos and bar codes) in large sizes primarily used for secondary packaging such as cases.

A beam of infrared light focused and steered with a series of carefully controlled small mirrors to create marks where the heat of the beam interacts with the packaging surface.

Label Printer Applicator (LPA)

Prints and places labels of various sizes on multiple package types.

Marketing opportunities

The safety and authenticity of eggs are persistent concerns in all regions of the world. Getting consumers to appreciate eggs as more than a commodity holds the key to greater loyalty and improved demand. Printing brand and egg information directly on the egg provides producers with an opportunity to improve brand differentiation and consumer loyalty through a clearly visible commitment to quality and safety.

Continuous Ink Jet (CIJ)

- ideal technology for in-line coding directly on eggs

- cost effective solution because it requires the fewest printers

- most efficient solution as printers are integrated with the grader for direct controlling from the console

- food-grade ink specially formulated to safely adhere to egg shells

Laser Marking Systems

- microscopically etches the surface of the egg to create a permanent imprint with no ink

- code clarity is less affected by moisture on the egg

- improved print quality over ink coding

Planning for the future

Egg carton packaging is changing as retailers try to attract consumers to more beneficial eggs. Carton design is also advancing as the simple package is being improved to provide better protection and egg coding visibility to minimise consumer interaction with the eggs. Coding solutions designed to perform well across a wide range of packaging styles and materials give the producer freedom to adapt to future changes.

Continuous Ink Jet (CIJ)

- simple and reliable way to print on paper, plastic and foam cartons and shrinkwrapped egg trays

- Videojet’s 1000 Line printers incorporate the CleanFlow™ printhead, a patented design that increases uptime by reducing ink buildup

- non-contact printer, making it a reliable solution for printing legible traceability codes

Laser Marking Systems

- delivers excellent character and logo print quality

- permanent print and virtually no mess

- can print across the top of an egg carton in multiple locations, even when the carton is stationary on the line

Thermal Ink Jet (TIJ)

- ink-based printing solution for porous carton materials like paper

- prints at a higher resolution than other ink-based systems

Thermal Transfer Overprinting (TTO)

- prints on overwrapped plastics prior to its application around a flat of eggs

- produces high quality codes using a ribbon-based printing system that also produces superior bar codes

Improve supply chain efficiency and save money

Printing lot, batch and supplier-specific information clearly on the egg case creates a traceability point visible to the retailer, wholesaler and transportation company – providing rapid identification in case of recall. Printing this information directly on the case simplifies packaging demands by standardising to a common box style for different trading partners.

Label Printer

Applicator (LPA)

- standard way to identify product for delivery to trading partners

- automated labelling solutions can significantly reduce mislabelling and poor readability for optimum routing and tracking

- automatic application of labels on-demand to cases is faster and more consistent than hand-labelling and prevents applying the wrong label

Large Character

Marking (LCM)

- prints information directly on the case including scannable bar codes

- very cost-effective and dependable

- eliminates the cost, stocking and management of labels, as well as the need for customer-specific pre-printed cases

Thermal Ink Jet

(TIJ)

- high resolution printing directly on the case

- ideal for printing on display ready cases

- prints a variety of bar code types to comply with retailer supply chain requirements

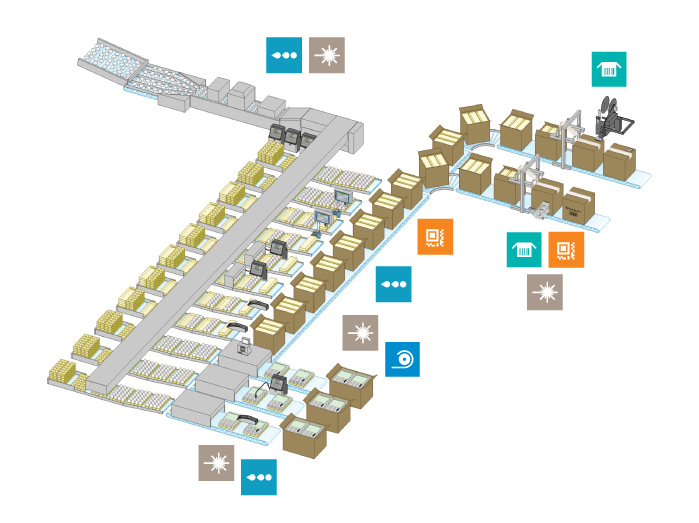

- Grader, Cartoner and Packer

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

Thermal Transfer Overprinting (TTO)

A digitally controlled printhead precisely melts ink from a ribbon directly onto flexible films to provide high resolution, real-time prints.

Ink-based, non-contact printing using heat and surface tension to move ink onto a package surface. Generally used to print 2D DataMatrix and other bar codes.

Ink-based, non-contact printing of multiple data types (alphanumeric, logos and bar codes) in large sizes primarily used for secondary packaging such as cases.

A beam of infrared light focused and steered with a series of carefully controlled small mirrors to create marks where the heat of the beam interacts with the packaging surface.

Label Printer Applicator (LPA)

Prints and places labels of various sizes on multiple package types.

- Brochures

- Application Notes

- Case Studies

Contact Us

Equipment Sales:

01267 6687

Service & Support:

+353 1 267 6503 (Republic of Ireland)

03301233930 (Northern Ireland)