Do you have a parts marking

partner that adds value

beyond the code?

Independent surveys conducted with over 300 automotive

and aerospace professionals identified top coding and

marking priorities in these industries.

See what they had to say:

Meeting customer specifications

A recent auto industry survey identified customer-specific requirements as one of the top two issues affecting both OEM and supplier quality1

1. Automotive Industry Action Group Quality 2020 survey

Customer-specific parts

marking requirements are

part of this challenge

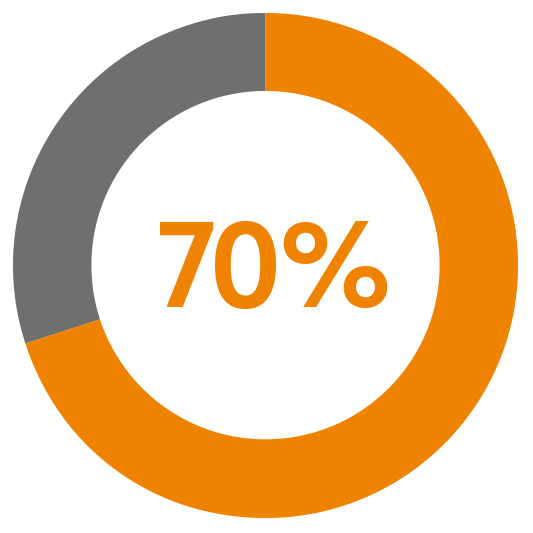

In fact, 70% of automotive and aerospace manufacturers agree that coding and marking suppliers can assist most by providing flexible solutions that help enable compliance across a range of product types and/or customer requirements.

Source: TechValidate survey of 217 users, published Jan. 31, 2017

Videojet customer testimonials

What is the greatest impact

Videojet has had on how you

serve your customers?

“Videojet has enabled us to give our customers the exact markings that they require.”

Gil Lane, Manufacturing Engineer, Magellan Aerospace Corporation

“Videojet has become the compliant standard across our customer base, saving us time.”

Tom Kelleher, Production Manager, EW Johnson

“Videojet has allowed us to meet the ‘Just in time’ requirement of our customers.”

Project Manager, Medium Enterprise Metals & Mining Company

“Great print quality for our downstream process customers.”

Project Engineer, Large Enterprise Industrial Manufacturing Company

“Videojet has allowed my company to meet customer demands and comply with guidelines set in place by the aerospace industry.”

Project Manager, Small Business Aerospace & Defense Company

Source: TechValidate survey of Videojet customers, published: Jan. 24, 2017

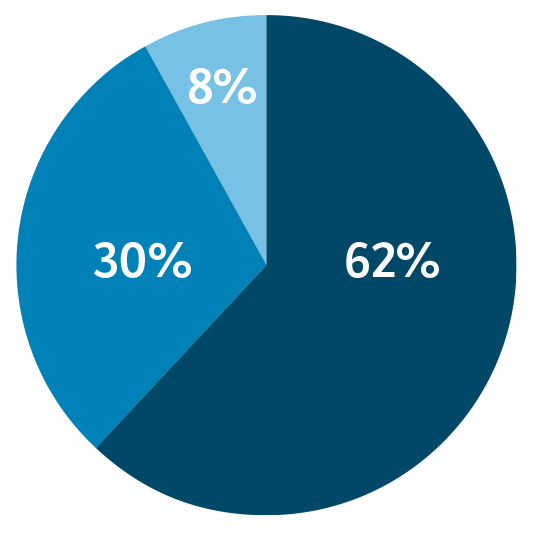

Coding and marking integration priorities

Simplicity is key for integrating into auto and aero production environments.

What is your top integration priority for coding and marking equipment in your facility?

Simplicity and ease of use: 62%

Maintenance and technical support: 30%

Connectivity with limited reconfiguration and adjustment: 8%

Source: TechValidate survey of 250 users, published Jan. 31, 2017

Videojet customer testimonials

“Videojet has provided unparalleled support and has kept us up and running. Very few, as in count on one hand, days of downtime related delays in marking / identifying our parts.”

Production Director, Fortune 500 Aerospace & Defense Company

“Aerospace requires 99% of parts to be marked, which was previously done by hand stamping. A Videojet system has saved a great deal of time in the marking process.”

IT Director, Small Business Aerospace & Defense Company

Sadique Nakedar, a Logistics Manager at Optibelt Power Transmission

India, would be very likely to recommend Videojet for this reason:

“Reliable, good quality, and easy to handle.”

Shea Koch, a Production Manager at Orbital ATK, would be very likely

to recommend Videojet for this reason:

“Any company wanting to work with its business partners to improve is a company I would recommend to a friend.”

Source: TechValidate survey of Videojet customers. Published: Jan. 24, 2017