Line management

Videojet understands the unique challenges you face on your cosmetic, personal care and home care production lines, from frequent packaging changeovers to coding more content in less space. These challenges can be reduced by enabling faster line set-up and changeovers, as well as dramatically reducing the opportunity for coding errors through efficient line management techniques. Packaging operations can use line management solutions such as Videojet CLARiSUITE® to help boost available production time, lower scrap and rework, and increase profit.

Automated or manual coding: Which is best for your coding needs?

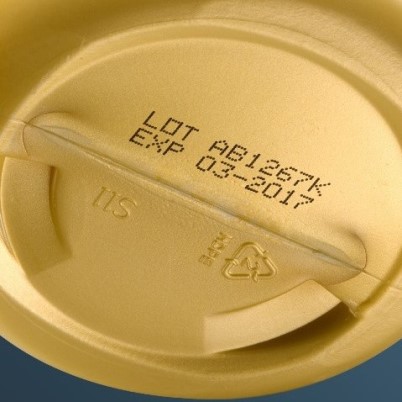

Cosmetics, personal and home care products with many scents or colours often necessitate customised packaging by batch. This can result in a large amount of pre-printed materials, increasing SKU complexity and increasing the risk of mislabelled products.

There are numerous ways to leverage value-added coding for your products to help reduce costs and manufacturing complexity.

Remote access with VideojetConnect™

Having the ability to quickly deal with production irregularities or faults can help you to minimize costs, reduce rework and lower scrap. VideojetConnect™ delivers on-board remote service capabilities, and can help you to act quicker and make an informed decision when any problems occur on your production line. Instant access to Videojet expertise is a click away.

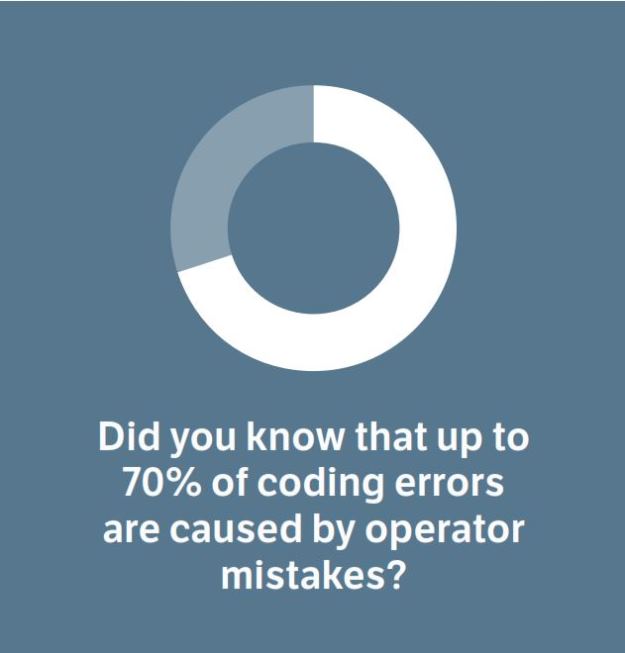

Code Assurance Solutions

Product coding during the packaging process is a key part of cosmetic, personal care and homecare manufacturing. Simplifying the process of message entry and selection through automated tools can greatly reduce coding errors, to help increase productivity, reduce waste and minimise operational costs. With the widest selection of coding technologies utilising an intelligent user interface, Videojet can help you to improve your coding processes.