What is Glass Laser Etching?

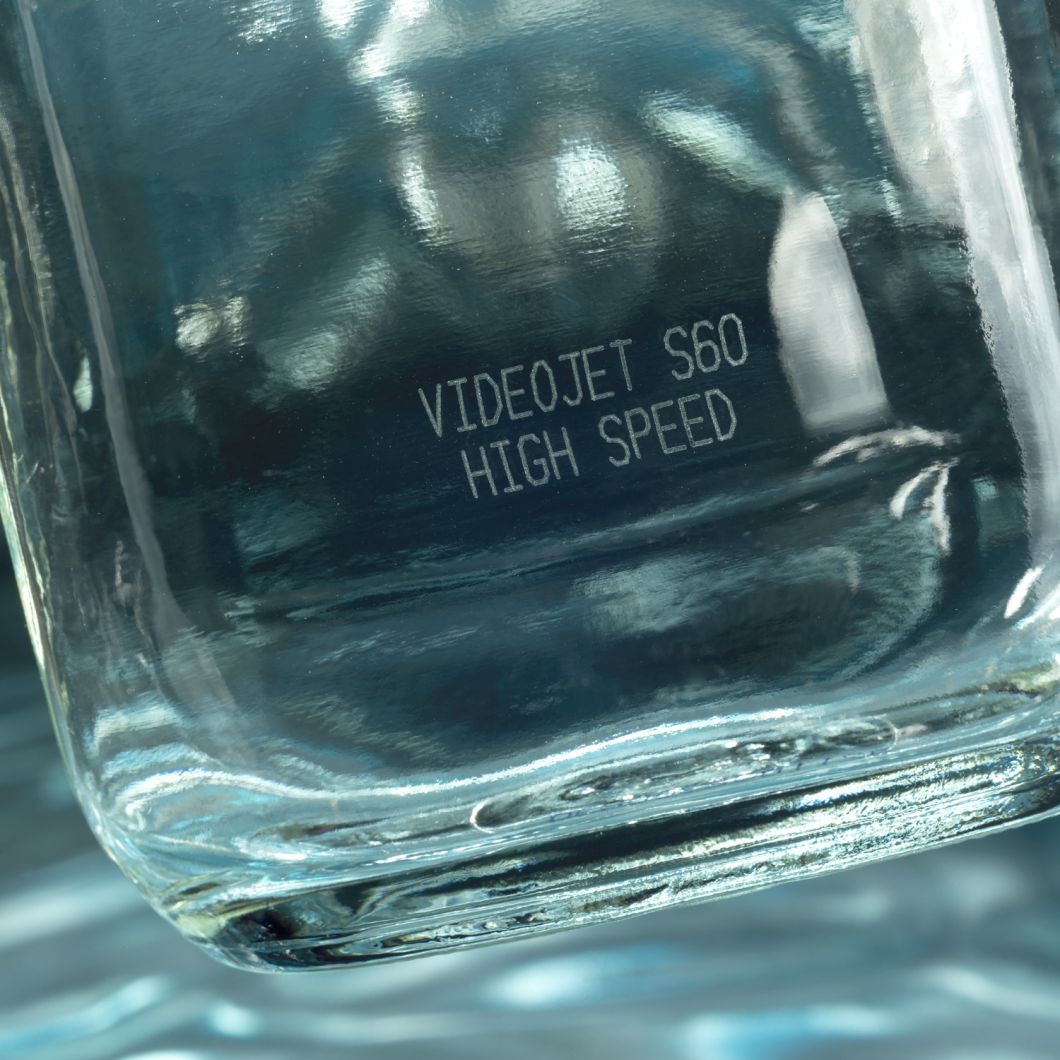

Laser etching glass (also referred to as laser engraving or marking) is an increasingly popular solution for printing on glass products and glazing. Laser marking machines allow permanent high-resolution codes and symbols to be etched onto nearly any colour or type of glass, from bottles and vials to glazing and other glass products. The precision of laser etching ensures excellent results, provided the power, speed, and focus are well controlled.

What is the difference between Laser Etching and Engraving Glass?

The main difference between laser etching and laser engraving is the depth to which the laser penetrates the glass surface, and the depth of the resulting mark. Typically, all other factors being equal, a higher powered laser will be required to engrave glass versus to etch it.

Advantages of Laser Etching Glass

Laser etching offers several advantages over traditional marking methods:

- Permanence: Laser Engraving marks are indelible and more durable than continuous inkjet printers, which can be altered or washed away in certain conditions.

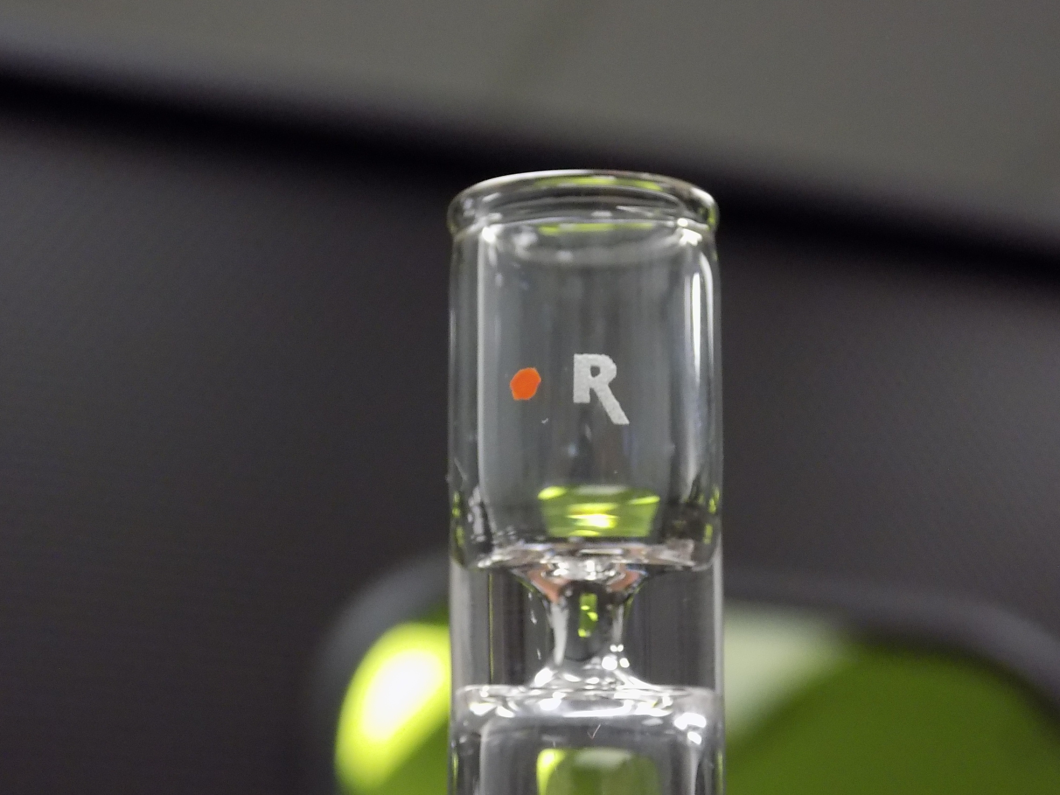

- Precision: Glass bottles, vials, and jars can be marked with detailed variable data, and quality marks.

- Resistance to Conditions: Ideal for environments with high moisture or where products are subject to handling that could damage printed codes.

- Security: Laser etched marks help protect against tampering and fraud, contributing to brand confidence.

Glass Laser Engraving and Etching Solutions

At the cutting edge of marking technology are systems like Videojet 3640 CO2 laser marker and Videojet 7810 UV laser coder. These systems are engineered to create precise micro-cracks on the glass surface, suitable for a wide range of applications including serial numbers and traceability information on both clear and coloured glass.

The adoption of laser glass etching into production lines is a testament to its efficacy. For instance, in a pharmaceutical & medical device, packaged food, or beverage marking, a laser beam is directed towards a rotating or vibrating mirror, which then traces out numbers and letters onto the glass products. This allows for “on the move” marking, a crucial feature for high-speed production lines.

Talk to Videojet about your application. 01267 6687

- Suggested Solutions

- Documents

Request a Free Quote

For Equipment Sales enquiries call us on:

Or send us your information to contact you: