It is the role of product labelling to accurately identify and describe a product, in order to enable consumers to make informed purchase and use decisions. Clear, accurate information labelling is a necessary part of complying with UK product regulations, but is also an important marketing and sales tool for product manufacturers.

Product labels carry information about where the product was made and by whom, and often include directions on how it is to be effectively used, the product’s ingredients and precise weight. For food and pharmaceuticals, labelling may also include manufacturing barcodes, allergen warnings, best before end date (the date after which food may no longer be considered safe to eat), traceability information, and details about how best to store and prepare it.

In addition to compliance with labelling legislation, the product label acts as the brand owner’s direct connection to the consumer, enabling them to showcase the brand and product benefits. Clear photos and colourful graphics often play an important part on pre-printed labels in presenting the product in a positive way.

Methods of Labelling Products

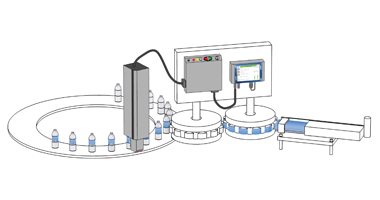

Label information may be printed directly onto flexible film material prior to packaging, printed on the packaged product itself, or on paper or plastic adhesive labels that can then be automatically applied online to the package surface. Some labels may be printed offsite or printed online prior to application.

Whether printed on the package or on an applied label, it is especially important that the printed label information be complete, clear and readable. Blurred printing, tears or folds in an applied label that make allergen warnings or expiration dates unreadable can directly affect consumer health and safety. Improperly formed codes, text and images also reflect poorly on the manufacturer’s brand image.

Labelling Pharmaceutical Products

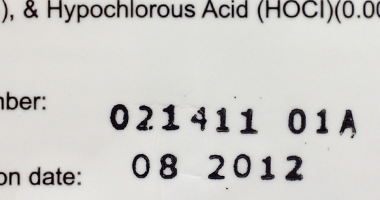

Various global regulations require pharmaceutical product packaging to bear unique individual identification codes that enable medications to be traced throughout the distribution system. For example, upcoming European regulations will require a UFI (unique formula identifier) to be printed on products that contain a hazardous mixture. The alphanumeric UFI code will enable poison control centres to advise proper treatment in the event of a crisis. Codes like these are printed on products online during the packaging process. Because of their importance, these codes are usually inspected by vision inspection systems immediately after printing to ensure their completeness and readability. Code regulations are subject to change and expand. Those using them must keep abreast of those changes to remain in compliance.

Categories

Contact Us

Equipment Sales:

01267 6687

Service & Support:

+353 1 267 6503 (Republic of Ireland)

03301233930 (Northern Ireland)